Scrap metal recycling is a crucial process that helps to reduce the environmental impact of metal production and conserve natural resources. The process involves collecting, sorting, and preparing scrap metal for melting and refining, transforming it into new products. Here’s a detailed look at the seven different stages of the scrap metal recycling process.

Know the Basics Before bringing your scrap metal to the recycling yard, it’s essential to separate metal from all other materials such as plastic or paper. Items that contain 50% or more metal are set aside, and a magnet is used to identify ferrous and non-ferrous metals.

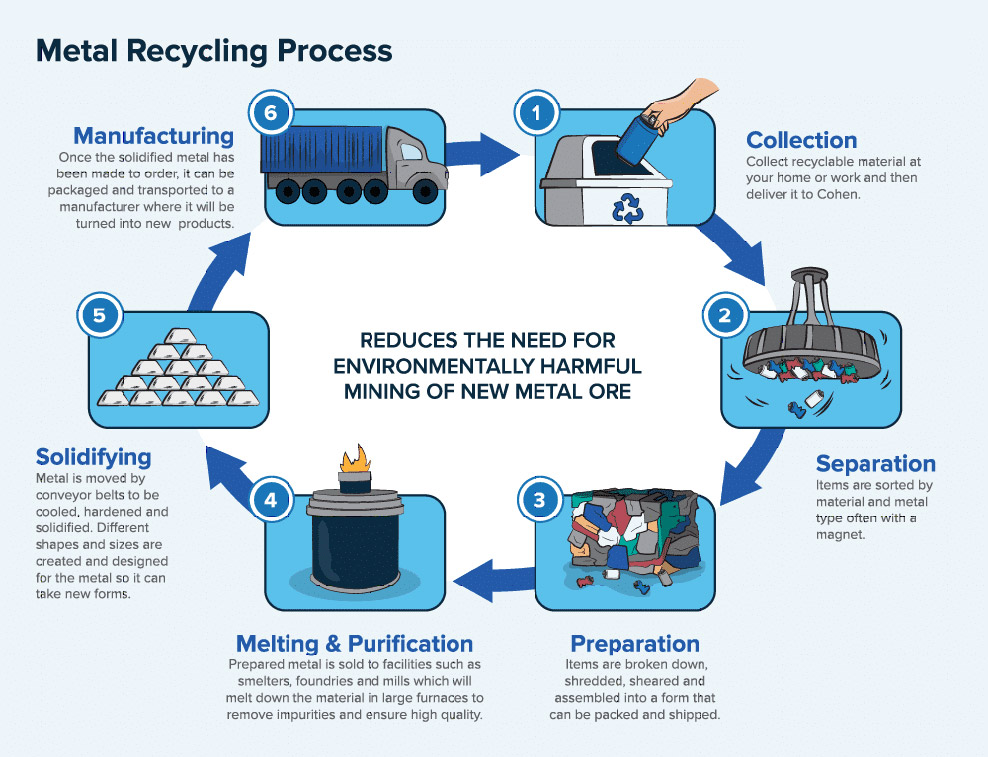

Collecting Scrap metal is collected from various sources, including scrap dealers, household curbside recycling, and large generators like oil companies. At the recycling yard, the material is weighed, and the client receives a weight ticket to cash in.

Sorting The sorting process involves visual identification, spectrometers, magnets, and electrical currents to separate different types of metals. This ensures that metals meet certain quality standards without cross-contamination with other metals and materials.

Preparing into Forms To make the melting process more efficient, scrap metal is cut down to specific sizes and shapes. Shredding, torching, and baling are all examples of ways that scrap metal can be prepared, depending on its final use.

Melting and Refining The melting process varies from one metal to the next, and the level of purity that’s needed. Melting metals makes impurities rise to the top, where they can be separated from the remaining metal. Some metals go through additional refinement through processes like electrolysis to yield something as close as possible to primary, or new, metal.

Solidifying Once cleared of contaminants, molten metal is transformed as it solidifies into various forms, including bars, wire, coil, and sheets. Sometimes, chemicals are added to the metal to make it denser or change its properties.

Manufacturing The foundry or mill is not the end user of the new metal. It goes on to other sectors of the manufacturing stream, like automakers, robotics, aerospace, public works projects, and a vast array of consumer goods. Through repair and reuse, the lifecycles of those products can be maximized until it’s finally time to recycle them again.

In conclusion, the scrap metal recycling process is a fascinating journey from waste to new products. By understanding the different stages, we can appreciate the importance of recycling and its impact on the environment. Recycling scrap metal not only conserves natural resources but also reduces energy consumption and carbon emissions. Let’s all do our part in ensuring a sustainable future by recycling scrap metal whenever possible.