Joint Venture Company

BEST ANGOLA RECYCLING, LDA

At BEST ANGOLA METAL, LDA, we are proud to announce our new project of installing a state-of-the-art Steel Industry with an automatic process and modern technology for the production of steel re-bars used in civil construction. This project, which was unanimously approved by our promoters in 2020, is being installed in the Industrial Development Pole of Viana in 2022 with an investment of USD 10,000,000. Our goal is to become the leading manufacturer of Fe 500 TMT Bars in the ANGOLA Market and create more than 300 job opportunities for the local people.

Our steel production starts with an annual capacity of 10,0000 MT for the manufacture of TMT Bars, and with the new technology of automatic rolling mills, our capacity increases to 100,000 MT per year. Our products have played an essential role in driving the construction boom in the ANGOLA Market. We are proud to say that our products are BIS certified, and our process has gained ISO certification for our unit.

At BEST ANGOLA METAL, LDA, we value the environment, and our production facilities are fully in conformance with environmental norms. We have enhanced our commitment to green manufacturing, and all our products are produced with a strong environment consciousness.

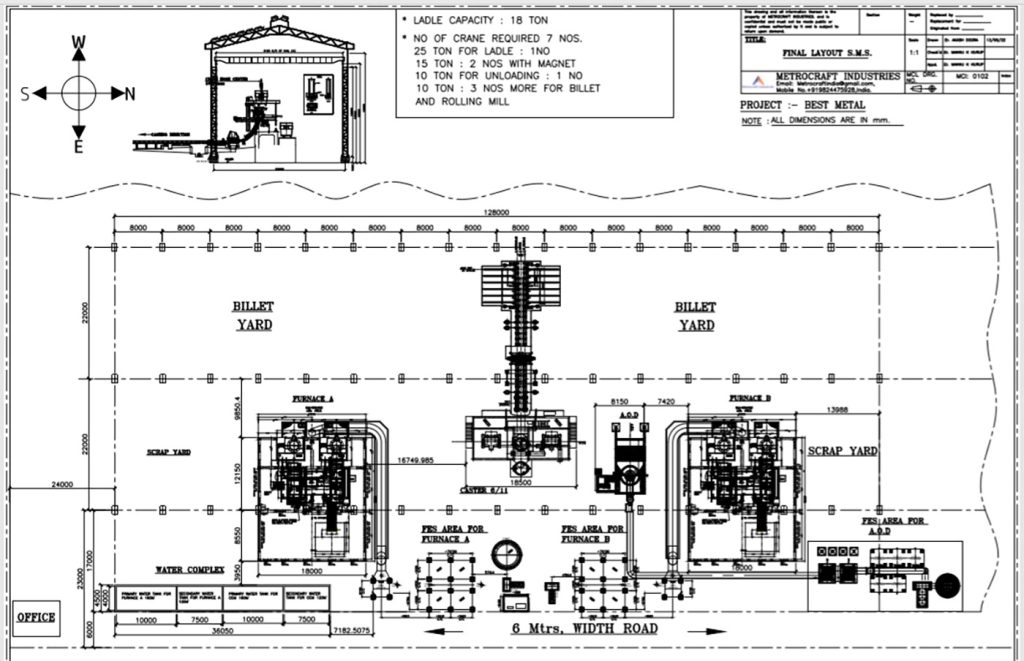

Our consented production capacity of the plant is to manufacture 10,0000 MTA, and to avoid large procurement of MS Billets from the local market, we propose a steel melting unit for the production of MS Billets of 100000 MTA capacity and a steel rolling mill of hot conditioned billets into rollers from the Caster machine. Our proposed melting unit features 2 No of 15 MT induction furnace with four crucibles. Only Two crucibles will be operated at a time for a furnace, and the other will be kept standby.

In summary, at BEST ANGOLA METAL, LDA, we are committed to producing high-quality steel products using modern technology while ensuring our production processes are in line with environmental norms. We look forward to starting our production in 2023 and becoming the leading manufacturer of Fe 500 TMT Bars in the ANGOLA Market.

PRODUCTION DETAILS

s.no | Particulars | Oty | Production |

1 | 15 ton Furnace 2 panel (4 crucible)at a time two crucible will work(33T X 10=330 X26Days=8580 X 12=102960 TON | 33 ton | 102960 |

2 | 6/11 Caster 2 Strand- total production -102000 T |

| -1930 |

3 | 18”Rolling mill -99000 T |

| – 2030 |

4 | The annual production loss and holidays 312 working days (not calculate other holidays )102960-99000=3960 (calculate holiday and production loss) |

|

|

5 | Total |

| 99000 Ton |

Plant Design and Layouts

The project site required 10 acre land . The proposed melting unit a activities will be carried out within this land itself.